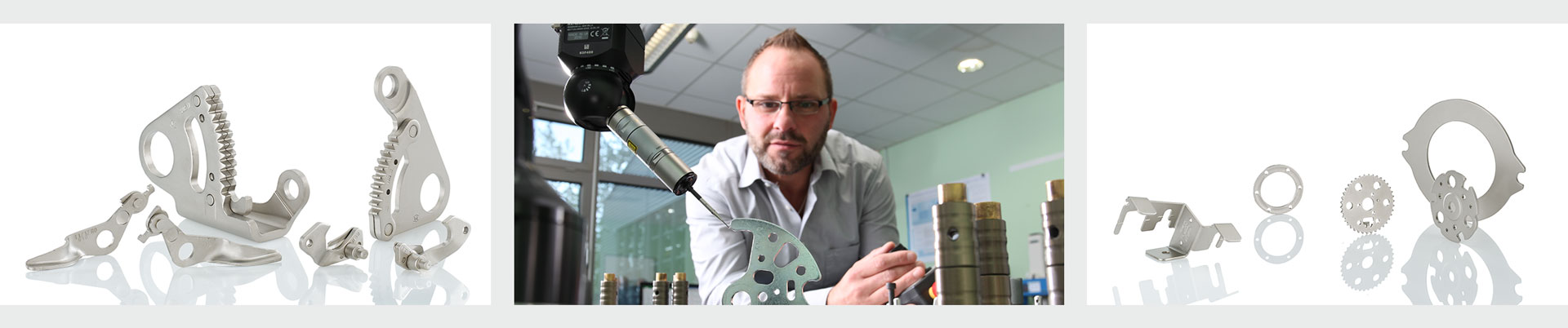

Engineering, fine blanking, stamping and forming

Design and tool making

- Our modern design departments develop and construct progressive, fine blanking and small tools depending on the required specifications.

- The tool making is performed inhouse, too, so that we can adapt flexibly to our clients’ demands and wishes.

Fine blanking

- In the process of fine blanking triple action presses ensure a more precise dimensional accuracy, improved surface and flatness values as well as cut edges free of tears and chips

- This economic procedure allows for a simultaneous forming of the components; a time-consuming post-molding treatment of the workpieces is no longer necessary.

- We manufacture these high-precision parts on 14 fine blanking units with a capacity of 280 up to 1.400t, which not only allow us to cut materials with thicknesses up to 14 mm but also to cut helical gears to the highest quality.

- Right from the beginning, exact cold forming and precisely defined annealing parameters in all the Mendritzki steel plants ensure an ideal input stock for the manufacturing of these special components.

Stamping

- The stamping process ensures a highly economical

production of three-dimensional sheet metals, which we reliably control even when it comes to tough, brittle-hard and fiber-reinforced materials. - The tools we construct and manufacture constitute a substantial part of our know-how and are used in our extensive press equipment.

- In addition to a CNC-controlled EXNER hydraulic press with a press capacity of 1.200t and a transfer system we also use Kaiser stamping

and forming presses with 500t and different eccentric presses. - This way we can always pick the appropriate process technology. The maximum available tool area has dimensions up to 3.000×1.500mm.

Bending and forming

- By reasonably combining stamping, bending and forming procedures we realize complex component geometries, which go far beyond simple punched parts.

- Therefore we often use deep drawing and extrusion procedures in the manufacturing of our tools.

Downstream processing

Deburring

- We got the right technology to deburr components

- In addition to the classical techniques like belt grinding, brushing or barrel finishing, we implement our highly automated CNC system especially for largescale manufacturing, thus, combining high economic efficiency and maximum process reliability due to a guaranteed machining on both sides.

- This way, we can deburr small and large components with the same efficiency as prototypes and large series.

Precision grinding

- By using Diskus double face grinding machines we achieve exact thickness tolerances and finest surfaces.

Sharpening and pointing

- We are specialized in the production of geared clutch discs, which are sharpened and further processed by using the latest CNC technology.

- Modern control and labeling systems ensure traceable and flaw-free components.

Soft and hard turning

- You can rely on us when it comes to precise components with narrow tolerances.

- We combine modern turning machines with individual measurement and testing technology to ensure safe procedures.

- When it comes to hardening we start where others break.

Joining and assembling

- Depending on customer requirements we construct assemblies out of self-manufactured individual components and purchased attachments.

- In the manufacturing of assemblies we apply procedures like welding, riveting and clinching.

- The degree of the plants‘ automation depends on the requirements and characteristics of the components and assemblies to be manufactured.

- Based on our extensive know-how in terms of automation we draw up respective concepts and units by internal contribution.

Heat treatment

- Inhouse, we perform various heat treatment processes as needed – like tempering, case hardening in multipurpose chamber furnaces, bainitic hardening in furnaces with salt bath quenching, hardening without distortion in quenching hardening plants, inductive hardening and annealing.

Surface treatment

- In terms of surface finishing we apply wear and corrosion protection methods like KTL coating, Zn|Zi coating and phosphating.

- Powder coatings can be applied to the workpieces in any RAL colour desired.

Plastic coating

- Often, a combination of steel and plastic results in the ideal product.

- In addition to highly precise steel components we also deliver these as hybrid components with plastic and just as precise.

- Almost every material can be chosen – even fiber-reinforced plastics.